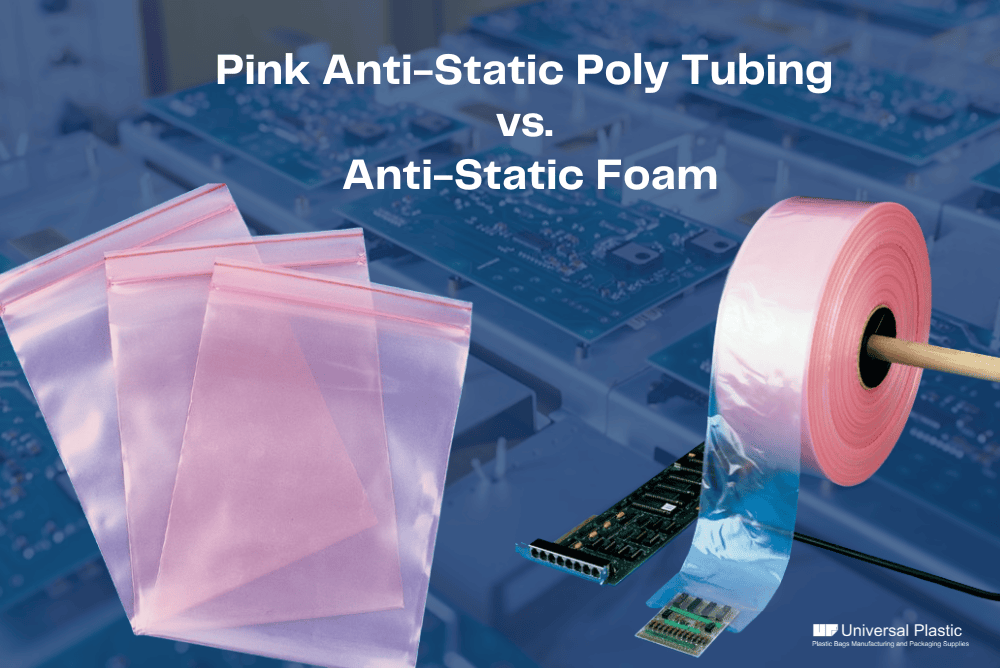

Anti-static packaging plays a vital role in the electronics manufacturing and shipping industries. This packaging protects electronic components from static electricity, which can accumulate and discharge suddenly, potentially damaging sensitive electronic circuits. This leads to direct financial losses in terms of component costs and impacts productivity and reputation due to delays and decreased final product reliability. Anti-static packaging solutions, such as pink anti-static poly tubing and foam prevent these occurrences. They protect electronic components from static charges and other factors. Pink anti-static poly tubing and foam both protect electronic components, but they have distinct characteristics and applications. This post offers you insights on the differences between these two material types.

Evaluating Anti-static Packaging – Pink Poly Tubing and Anti-static Foam

Here are some pointers that give a competitive analysis of pink poly tubing and other anti-static solutions. Let’s have a look at them.

- Protection Capabilities: Pink poly bags are made of plastic material comprising conductive and non-conductive layers and treated to dissipate electricity. When delicate electronic components are placed inside the bag, any static electricity built up on the component surface or the bag is dissipated quickly through the conductive layer. This prevents the static charge accumulation that can damage sensitive electronic parts. Some pink anti-static bags also provide a Faraday Cage effect. This helps protect the delicate electronics from external static electricity, as well as electromagnetic interference. This also helps protect the components from accidental discharge. Anti-static foam is a cushioning material that protects electronic components from static electricity and physical damages. This foam offers superior cushioning effect and absorbs shocks during transportation, reducing the risk of mechanical damage. Such cushioning is vital when handling products like delicate sensors, or intricate electronic assemblies that require both impact resistance and static control.

- Humidity Control: Many pink poly bags feature a layer of moisture barrier material that help control humidity levels inside the bag. This feature helps prevent the static charge buildup, especially in dry environments. However, this feature cannot be found in anti-static foam.

- Flexibility and Customization: Pink poly tubing can used to package large items or cut to fit small objects. This makes it suitable for various electronic components, from tiny chips to large boards. Foams can be custom-cut and shaped to fit each application, which can restrict their quick usability unless pre-cut options that suit the object sizes are available.

- Environmental Impact: Pink ESD bags are often single-use; however, some recyclable options are available, too. Anti-static foams are usually more reusable and contribute to less waste over the time.

- Cost-effectiveness: The cost of anti-static materials varies based on their usage and efficiency. Pink anti-static poly tubing is often considered a cost-effective solution for several reasons. First, poly tubing can be cut to any length, which means it can be tailored to fit an item perfectly without excess material, which minimizes waste. Additionally, its adaptability to suit various product sizes reduces the need for multiple types of packaging materials, potentially lowering inventory costs. Compared to pink poly tubing, anti-static foam can be more expensive. This is because anti-static foam is typically pre-sized, and using them may involve choosing from a range of sizes or ordering custom sizes, both of which can increase costs.

The selection of the right anti-static packaging solution entirely depends on the specific needs of your applications. The adaptability and cost-effectiveness of the pink anti-static bags make them a popular choice for a wide range of applications. Whatever packaging option you choose, ensuring the protection of your electronic components from static damage is crucial. Each material offers unique benefits, and the best choice will balance protection, cost, and the specific needs of your products. Universal Plastic is a leading supplier of static-proof bags, precisely crafted to protect sensitive electronics from static damage during storage and transportation. You can rely on us for quality and experience the confidence that comes with superior protection. Secure your electronics with Universal’s exclusive range of pink ESD bags. Contact our team to know more about anti-static packaging solutions.